Cotton is soft, fluffy, natural cellulosic, staple fiber that growns in a boll or protective shell around the seeds of the cotton plants of the genus Gossypium in the mallow family Malvaceae.

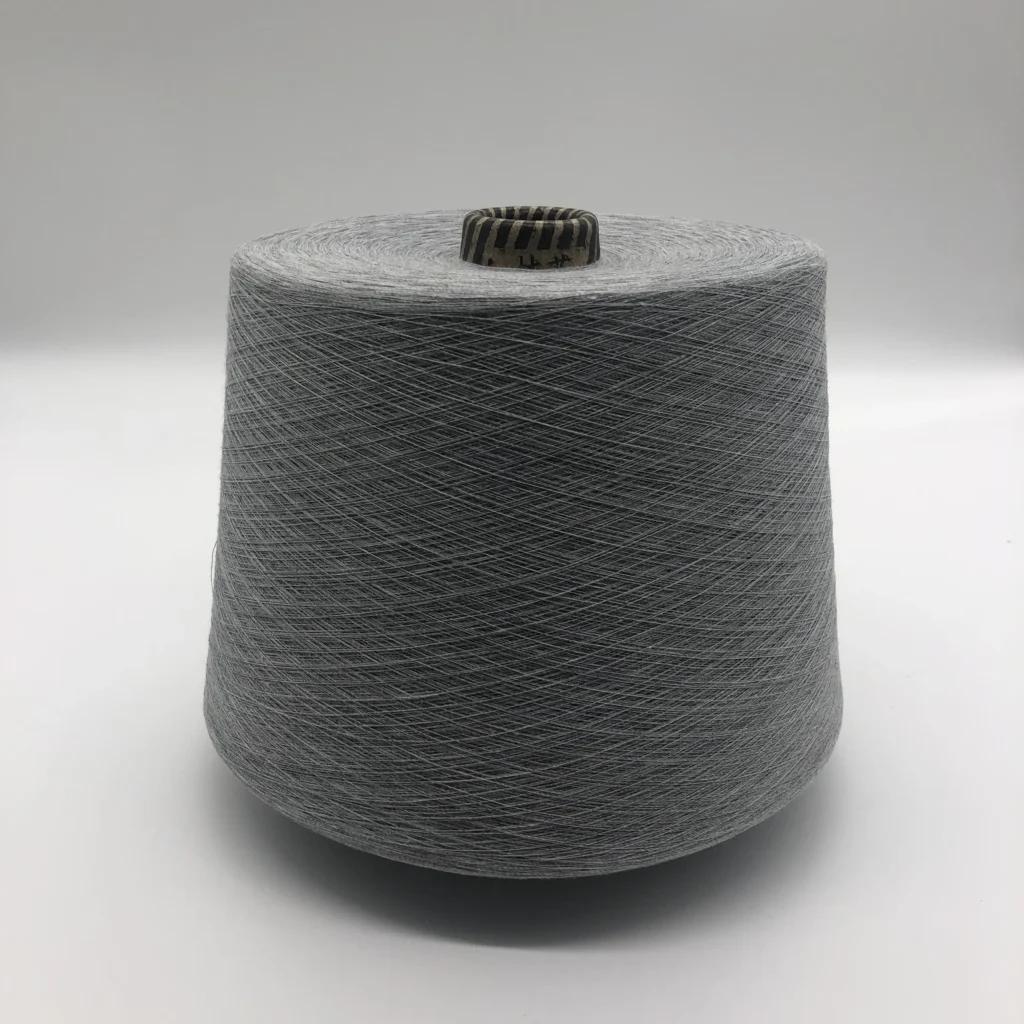

Ring carded and combed cotton yarn

Ring carded and combed compact yarn

Siro, Airjet Vortex, Rotor Open End, Core Spun, Twisted and Dyed yarn

Contamination Free, white guaranteed, merserised, BCI

- Usa Cotton

- Supima Cotton

- Egyptian Giza Cotton

- Turkish Cotton

- Cmia Cotton

- Bci Cotton

- Organic Cotton

- Gmo Free Cotton

ECOVERO

The raw material of viscose is beech tree; It consists of cellulose, just like cotton. There is almost no chemical change in the structure of cellulose, which becomes fluid during the viscose production process. After it hardens as a filament, it remains as cellulose. With these features, the structure of viscose is very similar to cotton.The moisture absorption ability of viscose is higher than cotton. Under normal conditions, it collects 11-14% moisture, and due to its high swelling feature, it can absorb up to 80-120% water.

Its dry durability is lower than cotton. Age durability is very low. When wet, its durability decreases by 40-70% compared to dry, and its elongation is 15-30%, twice as high as cotton. Viscose is very suitable for dyeing and printing due to its moisture absorption feature, which is much higher than cotton. It also makes colors appear brighter.

Viscose fabrics are elegant and comfortable. Due to the delicate and smooth spinning feature of the fiber, a soft touch is achieved in the product. It is slippery and compatible with the skin. Therefore, it is comfortable and easy to wear. It is used to give a shine effect on fabrics that need to be shiny, crepe fabrics and knits.

It is preferred in lining fabrics, blouses, shirts, t-shirts, dresses, decorations and women’s underwear production. Viscose fiber is also used by mixing it with other fiber types such as cotton, linen and wool.

Modal fiber is a type of semi-synthetic cellulose fiber, similar to rayon, that is made from beech tree wood pulp. It is known for its softness, smooth texture, and high moisture absorption properties, making it a popular choice in the textile industry for garments like underwear, activewear, bed linens, and towels.

Here are some key characteristics of modal fiber:

Softness and Comfort: Modal fibers are renowned for being incredibly soft and comfortable to wear. They have a silky feel against the skin, often compared to cotton and silk.

Moisture-Wicking: Modal has excellent moisture-wicking properties, absorbing up to 50% more moisture than cotton. This makes it ideal for garments worn close to the skin, especially in warm or humid conditions.

Durability: Modal is relatively durable, even when washed multiple times. Unlike other cellulose-based fibers, modal retains its softness and does not shrink as much. It also resists pilling, which helps maintain its appearance.

Breathability: Like cotton, modal is breathable, which helps regulate temperature and prevent discomfort from sweat buildup.

Eco-friendly: While modal is a synthetic fiber, it is considered more eco-friendly than many other synthetic fibers because it is made from renewable wood pulp. Additionally, some manufacturers use closed-loop processes to recycle the chemicals and water used in production, reducing environmental impact.

Versatility: Modal is often blended with other fibers like cotton, spandex, or polyester to enhance specific properties like elasticity or durability, making it adaptable for a wide range of textile applications.

Overall, modal is a popular and sustainable alternative to synthetic fabrics like polyester, offering a luxurious feel and superior moisture management.

Tencel, a brand name for a type of lyocell fiber, is a sustainable and eco-friendly textile made from wood pulp, primarily sourced from eucalyptus, beech, and spruce trees. The fiber is produced through a closed-loop process, which recycles water and solvents, minimizing environmental impact. Tencel is known for its luxurious feel, moisture-wicking properties, and biodegradability.

Here are some key characteristics of Tencel fiber:

1. Softness and Comfort

Tencel is incredibly smooth and soft, often compared to silk or cotton. It is gentle on the skin and has a natural sheen, giving it a luxurious feel, making it ideal for clothing, bed linens, and undergarments.

2. Moisture-Wicking and Breathable

Tencel fibers are highly absorbent, capable of absorbing moisture away from the skin and keeping you dry. They also allow air to flow through, promoting breathability. This makes Tencel garments great for activewear and warm climates.

3. Sustainability

One of Tencel’s biggest selling points is its environmental sustainability. The closed-loop manufacturing process used to produce Tencel recycles water and solvents, reducing the use of harmful chemicals and minimizing waste. Additionally, the raw material, wood pulp, comes from sustainably managed forests, making Tencel an eco-friendly fiber.

4. Durability

Tencel is strong both when wet and dry, which gives it high durability. It resists shrinkage, stretching, and fading, and is also resistant to wrinkles, which helps it maintain its look over time.

5. Biodegradability

Unlike many synthetic fibers, Tencel is biodegradable, meaning it will break down naturally over time without contributing to environmental pollution. This adds to its appeal for consumers seeking more sustainable and eco-friendly products.

6. Hypoallergenic

Tencel is gentle on the skin and hypoallergenic, making it suitable for people with sensitive skin or conditions like eczema.

7. Versatility

Tencel is highly versatile and can be used in a wide range of applications, from clothing (like shirts, dresses, and activewear) to bedding, towels, and other textiles. It can be blended with other fibers such as cotton, wool, and silk to enhance the fabric’s properties.

8. Eco-Friendly Process

The production process of Tencel is considered environmentally friendly compared to other fibers like polyester. The solvents used in the closed-loop process are non-toxic and are nearly 100% recycled, which reduces the environmental impact.

In summary, Tencel (lyocell) is a highly sustainable, biodegradable fiber known for its softness, moisture management, and eco-friendly production process. It’s a popular choice for eco-conscious consumers looking for high-performance, comfortable fabrics that have a minimal environmental footprint.

Viloft is a type of specialty fiber made from cellulose derived from wood pulp, similar to other fibers like modal and lyocell. It is a regenerated cellulose fiber, meaning it is produced through a process that transforms natural plant-based materials (usually wood or bamboo) into fibers suitable for textile production. Viloft is known for its unique properties that combine softness, moisture-wicking, and thermal performance, making it an excellent choice for a variety of applications, especially in cold-weather clothing.

Key Characteristics of Viloft Fiber:

Thermal Insulation: Viloft fibers are designed to have a hollow core structure, which gives them excellent insulating properties. The hollow channels trap air, providing warmth while remaining lightweight. This makes Viloft particularly suitable for thermal underwear, outerwear, and cold-weather garments.

Softness and Comfort: Viloft has a smooth texture, which contributes to its softness and comfort when worn next to the skin. It is often compared to wool or cashmere in terms of feel, though it is much lighter. This makes it ideal for underwear, t-shirts, socks, and sportswear.

Moisture-Wicking: Like other cellulose fibers, Viloft has excellent moisture-absorbing properties. It can absorb moisture away from the skin, keeping the wearer dry and comfortable. This quality also helps with temperature regulation, making Viloft garments suitable for activewear.

Breathability: Viloft fibers are breathable, meaning they allow air to flow through the fabric. This is beneficial in preventing overheating or discomfort from sweat accumulation, which is why Viloft is often used in sportswear and performance clothing.

Eco-Friendly Production: Viloft is produced using sustainable, renewable resources, usually wood pulp, and the process involves fewer harmful chemicals compared to conventional synthetic fibers. While it is a regenerated fiber (like Tencel or modal), the production process tends to be less resource-intensive. The fiber can also be biodegradable, depending on the specific manufacturing methods used.

Durability: Viloft has good durability, though it may not be as strong as some synthetic fibers like polyester or nylon. However, it holds up well in typical uses like thermal undergarments and sportswear, and it retains its shape and texture after multiple washes.

Versatility: Viloft can be used in a variety of fabric blends and applications. It is often mixed with other fibers, such as cotton, wool, or spandex, to enhance its properties. It’s commonly found in socks, activewear, thermal clothing, and sleepwear.

Hypoallergenic: Like many other cellulose fibers, Viloft is hypoallergenic and tends to be gentle on the skin, making it a good option for individuals with sensitive skin or allergies to synthetic fibers.

Common Applications of Viloft Fiber:

- Thermal clothing: due to its insulating properties, Viloft is popular in products like thermal underwear, sweaters, and coats.

- Sportswear and activewear: moisture-wicking and breathable qualities make it ideal for performance gear.

- Underwear and socks: Viloft’s softness and moisture management make it a comfortable and practical choice for everyday clothing.

- Bedding and sleepwear: the softness and thermal insulation properties also make Viloft suitable for sleepwear and comforter fillings.

Summary:

Viloft is a cellulose-based, sustainable fiber that offers excellent thermal insulation, breathability, and moisture-wicking capabilities. It is soft, comfortable, and eco-friendly, making it suitable for a variety of applications, especially in cold-weather clothing and activewear. With its hypoallergenic properties and versatile nature, Viloft is a great choice for consumers seeking high-performance, comfortable, and environmentally responsible textile options.

Bamboo fiber is a natural textile fiber made from the pulp of the bamboo plant. It has gained popularity in the textile and fashion industries for its eco-friendly production process and desirable properties, such as softness, breathability, and sustainability. Bamboo fiber can be processed in two main ways: mechanical (natural bamboo fiber) and chemical (viscose bamboo or bamboo rayon).

Types of Bamboo Fiber:

Mechanical Bamboo Fiber:

- This is the more natural form of bamboo fiber, made by crushing and grinding bamboo stalks, then using natural processes to extract the fibers. The process is environmentally friendly but labor-intensive and often results in coarser fibers. This type of bamboo fiber is typically used in bamboo linen or bamboo yarn.

Chemical Bamboo Fiber (Bamboo Viscose or Bamboo Rayon):

- This is the more common form used in textiles. Bamboo stalks are chemically processed into a pulp, then spun into fibers through a viscose process, similar to rayon. This method results in a softer, finer fiber that is more suitable for fabrics. However, the chemical process can be environmentally harmful if not done responsibly.

Key Characteristics of Bamboo Fiber:

Softness and Comfort: Bamboo fabric is extremely soft and has a silky texture, making it comfortable to wear. It is often compared to cotton or even silk in terms of feel, and is gentle on the skin, making it suitable for sensitive skin types.

Moisture-Wicking and Breathability: Bamboo fiber is highly absorbent and breathable. It can absorb moisture away from the body, which helps to keep the skin dry and comfortable. This moisture-wicking property makes bamboo fiber a popular choice for activewear, sportswear, and underwear.

Antibacterial and Odor-Resistant: One of the standout features of bamboo fiber is its natural antibacterial properties. Bamboo contains a substance called bamboo kun, which helps resist bacteria and fungi. This makes bamboo fabrics naturally odor-resistant and ideal for use in underwear, socks, and bedding.

Thermal Regulation: Bamboo fiber has natural thermoregulating properties, meaning it helps to keep the body cool in hot weather and warm in cooler conditions. This makes it suitable for year-round use and ideal for sleepwear and bedding.

Eco-Friendly: Bamboo is a highly renewable resource. It grows quickly without the need for pesticides or fertilizers and requires very little water compared to crops like cotton. However, the environmental impact of bamboo fiber depends largely on how it’s processed. The mechanical method is more environmentally friendly, while the viscose process can involve the use of chemicals and water, which can be harmful if not properly managed. That said, bamboo is generally considered more eco-friendly than many synthetic fibers.

Biodegradable: Bamboo fiber is biodegradable, meaning that it will decompose naturally over time, unlike many synthetic fibers like polyester. This adds to its appeal as an environmentally conscious material.

Durability: Bamboo fiber is generally strong and durable, though it can be more prone to damage when exposed to heat or harsh detergents. It is resistant to stretching, fading, and pilling, which helps garments maintain their appearance over time.

UV Protection: Bamboo fiber offers some degree of natural UV protection. It can help block a portion of harmful ultraviolet rays, making it a good option for clothing that is worn in the sun.

Common Applications of Bamboo Fiber:

- Clothing: Bamboo fabric is used in a variety of clothing items, including t-shirts, underwear, socks, activewear, and sleepwear. Its softness and moisture-wicking properties make it a comfortable option for daily wear.

- Bedding: Bamboo sheets, pillowcases, and blankets are popular for their softness, breathability, and antimicrobial properties.

- Towels: Bamboo towels are known for their absorbency and softness, making them highly sought after in bath linens.

- Home Goods: Bamboo can also be used in furniture, floor mats, and other household textiles.

- Eco-Friendly Products: Bamboo is used in a variety of eco-friendly products, such as biodegradable toothbrushes, kitchenware, and cleaning cloths.

Pros and Cons of Bamboo Fiber:

Pros:

- Soft and comfortable, often compared to silk.

- Highly absorbent and breathable.

- Naturally antibacterial and odor-resistant.

- Eco-friendly, especially when produced using the mechanical process.

- Biodegradable and sustainable when sourced responsibly.

Cons:

- Chemical bamboo fiber (bamboo rayon) involves environmental concerns related to the viscose process.

- Durability may vary depending on how the fabric is processed.

- Can be more expensive than conventional cotton or synthetic fibers.

Summary:

Bamboo fiber is a natural, sustainable, and versatile textile that offers many desirable properties, including softness, moisture-wicking, breathability, and antibacterial qualities. While the mechanical process for producing bamboo fiber is the most eco-friendly, the chemical process (bamboo rayon) is more common and can have environmental drawbacks if not handled responsibly. Bamboo fabrics are popular for clothing, bedding, and towels, and they offer a comfortable, environmentally conscious alternative to synthetic fibers.